PEEK Planetary Gear Reducer: A Precision Transmission Innovation

The PEEK planetary gear reducer is a high-precision reduction device with PEEK composite as core transmission components. Its core highlights lie in combining advanced PEEK material advantages with classic planetary transmission structure, achieving a perfect balance of lightweight, high precision, strong environmental adaptability and long service life. Below is a focused intro on its key highlights from four aspects:The PEEK planetary gear reducer is a precision reduction device with its core transmission components made of polyetheretherketone (PEEK) composite material. PEEK planetary gear reducer stands out in the field of precision transmission by perfectly integrating the excellent properties of PEEK composites with mature planetary gear technology, boasting significant advantages such as lightweight, high strength, wear resistance, and high precision. Here is a detailed introduction from four aspects: structure characteristics, material advantages, performance parameters, and typical applications:

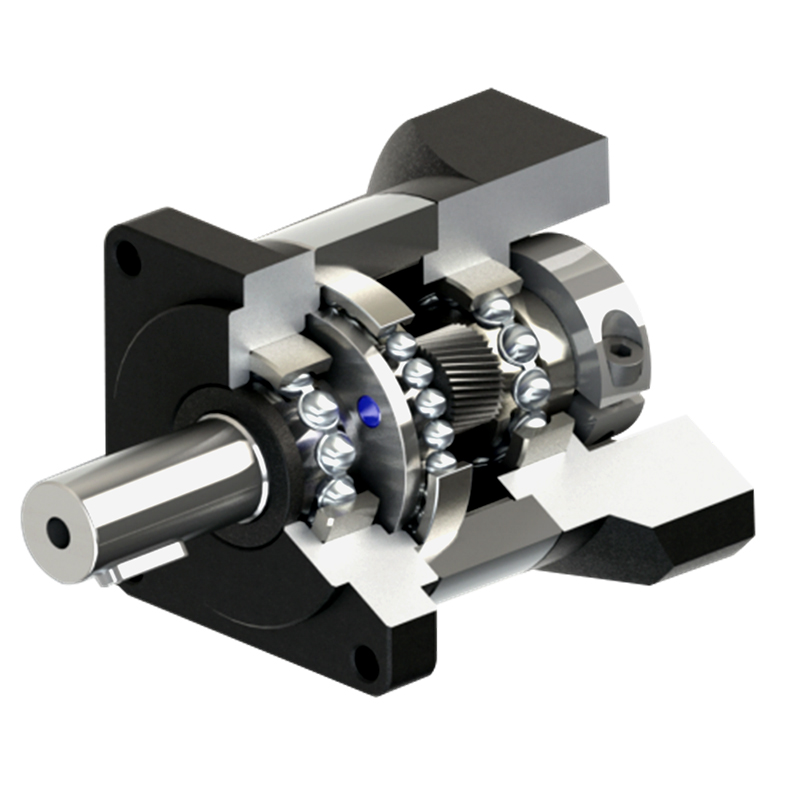

1. Structural Characteristics

High-precision structural design: Adopts classic sun gear-planetary gear-inner gear structure. Core gears (planetary, sun) use carbon fiber reinforced PEEK injection molding, reaching ISO 1328-1 Grade 6 tooth accuracy — a key guarantee for ultra-precise transmission.It adopts the classic and reliable planetary transmission structure of sun gear - planetary gear - inner gear, which ensures stable power distribution and transmission. The core gear components (planetary gear, sun gear) are manufactured by injection-molding with high-performance carbon fiber reinforced PEEK composite. This material selection not only enhances the gear's mechanical strength but also enables the tooth shape accuracy to reach the strict ISO 1328-1 Grade 6 level, laying a solid foundation for ultra-precise motion control.

Efficient & stable power output: Planetary carrier features integrated PEEK-metal composite structure, combining PEEK's lightweight with metal shaft sleeves' strength. It achieves ssshhh97% transmission efficiency and ≤1 arc minute return clearance, ensuring low energy loss and high motion accuracy.The planetary carrier adopts an innovative integrated PEEK - metal composite structure. It takes advantage of PEEK's lightweight and corrosion resistance while embedding high-strength metal shaft sleeves to ensure reliable power output. This optimized structure contributes to an overall transmission efficiency of ssshhh97%, minimizing energy loss during operation, and a return clearance of ≤1 arc minute, which is crucial for applications requiring high positional accuracy.

2. Material Advantages

Unique PEEK Material Advantages (Core Highlights)The PEEK composite material is the core of the reducer's superior performance, bringing three prominent material advantages:

Extreme Lightweight: Density only 1.3-1.5g/cm³, 40%-60% lighter than steel reducers — solves load-sensitive issues for humanoid robots, UAVs and other equipment.Lightweight: The density of PEEK composite is only 1.3-1.5g/cm³, which is significantly lower than that of steel. Compared to traditional steel-based reducers, it reduces the weight by 40%-60%. This lightweight feature is particularly suitable for scenarios with strict load sensitivity, such as the moving joints of humanoid robots and the payload-limited unmanned aerial vehicles, effectively reducing the overall energy consumption and improving motion flexibility.

Superior Environmental Resistance: Stable operation at -50℃ to 200℃, resists oil/acid/alkali corrosion, and adapts to humid/dusty environments — suitable for harsh industrial and aerospace scenarios.Environmental Resistance: It exhibits excellent adaptability to extreme environments, with a working temperature range from -50℃ to 200℃, enabling stable operation in both cold polar regions and high-temperature industrial sites. Additionally, PEEK planetary gear reducer has strong resistance to oil, acid, and alkali corrosion, and can maintain long-term reliable operation in humid or dusty harsh working conditions without performance degradation.

g & Low Maintenancelubricating oil reliancecutting significantlySelf-lubrication: The surface friction coefficient of PEEK composite is as low as 0.08-0.12 even under non-lubricated conditions. This inherent self-lubricating property greatly reduces the reliance on lubricating oil, avoids the risk of oil leakage污染, and significantly lowers the frequency and cost of maintenance, making it more suitable for clean operation environments.

3. Key Performance Parameters

Outstanding Performance ParametersThe reducer's excellent performance is quantified by its outstanding key performance parameters, covering various operational requirements:

Reduction Ratio: The reduction ratio ranges from 5:1 to 100:1, which can be flexibly configured through single-stage or two-stage combination. This wide range fully meets the diverse speed reduction needs of different mechanical systems, from low-torque high-speed to high-torque low-speed applications.

Rated Torque: The rated torque varies from 5 to 500N·m depending on the model series. This broad torque coverage allows the reducer to provide sufficient power output for different load requirements, whether it's light-duty precision control or heavy-duty power transmission.

4. Typical Applications

Maximum Speed: The maximum input speed is ≤10000rpm, which enables the reducer to adapt to high-speed working conditions. PEEK planetary gear reducer can maintain stable performance even when matching high-speed motors, expanding its application scope in high-speed transmission systems.

Widely Applicable in High-Demand FieldsBenefiting from its comprehensive advantages, the PEEK planetary gear reducer has been widely applied in various high-demand fields, playing an irreplaceable role:

Humanoid Robots: PEEK planetary gear reducer serves as the core power component for key motion joints such as hip joints and elbow joints. For example, in the leg drive module of the U-biqi Walker X humanoid robot, the lightweight characteristic of the reducer effectively reduces the load on the robot's limbs, while its high precision ensures smooth and accurate movement of the joints, enhancing the robot's motion flexibility and balance control capabilities.

Service Life: Under rated working conditions, the fatigue life of the reducer exceeds 10000 hours, which is equivalent to the continuous operation of humanoid robots for 1.1 years. This long service life significantly reduces the frequency of equipment replacement and maintenance, improving the overall operational efficiency of the system.

Industrial Automation: PEEK planetary gear reducer is widely used in end effectors of collaborative robots and precise conveyor belt drive systems. In collaborative robot end effectors, the high transmission efficiency and small return clearance enable the robot to complete delicate operations such as precise assembly and material handling with high accuracy. In precise conveyor belt drives, PEEK planetary gear reducer ensures the stable and accurate conveying of materials, improving the overall production efficiency and product quality of the automation line.

Aerospace: PEEK planetary gear reducer is applied in small satellite attitude adjustment mechanisms and onboard equipment of unmanned aerial vehicles. Its excellent environmental resistance allows it to operate stably in the harsh space environment with extreme temperature changes and vacuum conditions, as well as in complex aerial conditions. The lightweight advantage helps reduce the launch weight of satellites and the load of unmanned aerial vehicles, thereby improving their operational performance and mission endurance.